DigiTacts – Contact Pressure Sensors

DigiTacts are a high-performance tactile sensor system best for use in embedded or OEM integration applications.

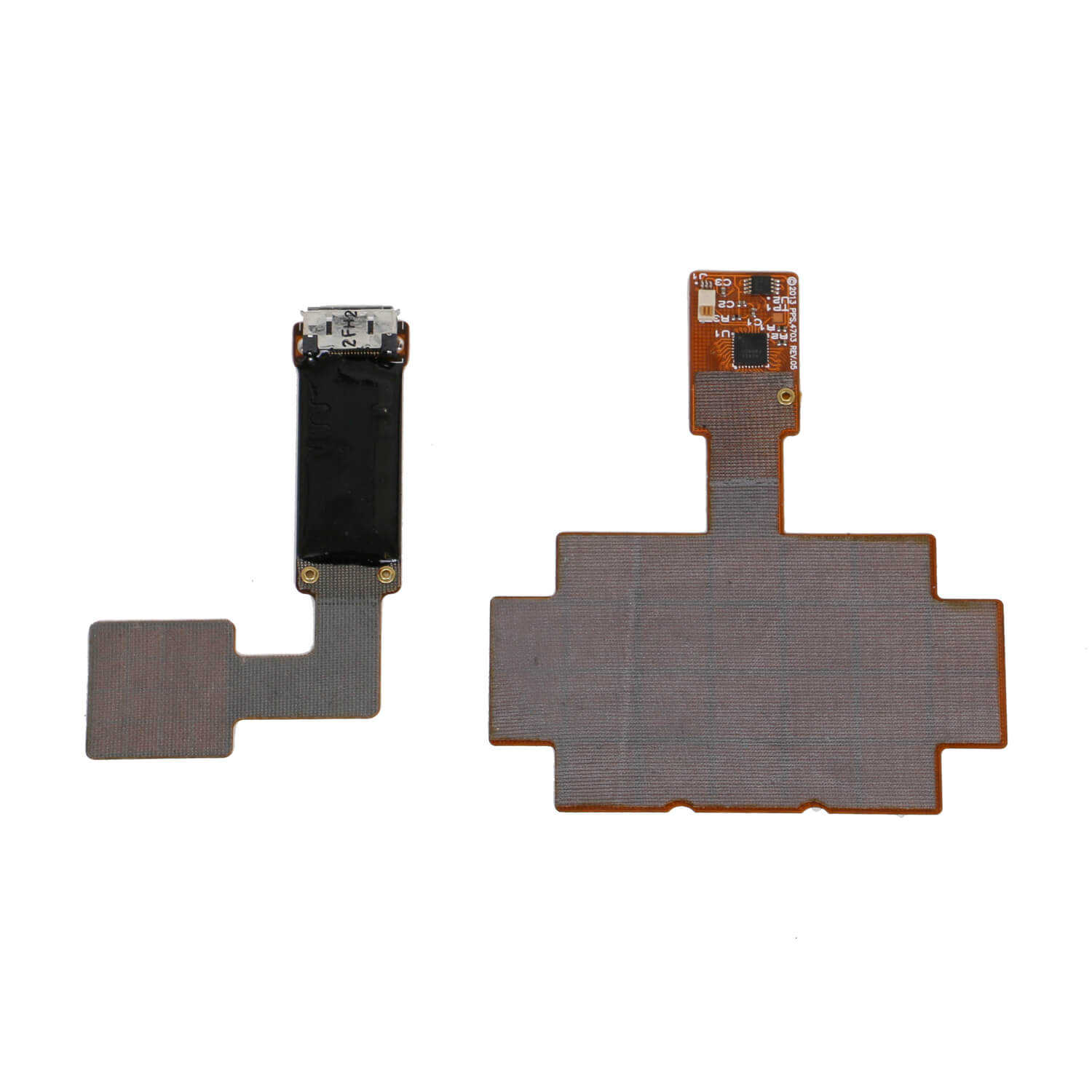

These extremely thin, flexible contact pressure sensors are available in multiple sizes, sensor configurations, and pressure ranges. DigiTacts enable accurate pressure measurement and real-time pressure distribution mapping between two surfaces across a wide range of processes and devices.

Currently trusted in the fields of medical devices, robotics, automotive, and consumer electronics, DigiTact sensors deliver compact, sensitive, and reliable data acquisition for innovative applications.

Features

Sensitive, stable, and repeatable sensor output that can be used in virtually any geometry - testing is not constrained by surface design.

High-performance capacitive sensing technology improves results and saves time by significantly reducing recalibration needs. DigiTact system achieves twice the repeatability, 100x better minimum pressure detection, and 50% better pressure sensing resolution compared to a traditional resistive tactile pressure sensor.

Compact, wireless Bluetooth electronics allow for simple and fast setup with minimal wiring complexity.

Chameleon Tactile Visualization and Acquisition Software enables users to export, replay, save, and analyse pressure data intuitively, with seamless integration into other analysis tools.

Description

DigiTacts sensors are ideal for product designers and engineers who wish to embed tactile pressure sensing into their systems. Each DigiTacts device consists of multiple sensing elements which measure the pressure applied at specific locations across the active sensing surface. Data is transferred via I²C or SPI digital interfaces, enabling easy integration into OEM products and flexible configurations for different applications.

All DigiTacts models include embedded microcontrollers, allowing them to function either as intelligent peripherals or complete control systems for simple applications. Depending on configuration, DigiTacts are sensitive enough to capture BP pulse waveforms yet rugged enough for contact pressure monitoring in demanding production environments. Multiple DigiTacts sensors can be combined to target areas of interest across larger surfaces.

We primarily offer DigiTacts as development kits for developers wishing to incorporate our tactile pressure sensing technology into new product designs. A DigiTacts Full System includes:

Two DigiTacts sensors (chosen design and pressure range)

Rechargeable U400 USB interface electronics or B400 with Bluetooth connectivity

PPS’ Chameleon Tactile Visualization and Acquisition Software

Chameleon enables intuitive pressure mapping, real-time visualisation, recording, replay, video integration, and data export for comprehensive analysis of contact pressure distribution.

Applications

DigiTacts sensors are suitable for a wide range of contact pressure measurement and pressure mapping applications, including:

Robotics and Automation: Integrate tactile pressure sensors into robotic hands, grippers, or end-effectors to measure pressure applied during manipulation tasks, improving dexterity, safety, and control.

Medical Devices and Wearable Technology: Embed contact pressure sensors into orthotics, prosthethesis, wearable health monitors, or patient positioning systems to enhance comfort, performance, and injury prevention.

Consumer Electronics: Incorporate tactile sensing into smart textiles, flexible interfaces, or next-generation user input devices to measure force and enhance user experience.

Automotive and Aerospace Systems: Use pressure sensors for in-cabin controls, occupant monitoring, ergonomic testing, or contact pressure distribution studies in advanced vehicle interior designs.

Industrial Process Monitoring: Monitor pressure applied during assembly processes, quality control checks, or material testing, ensuring consistency and improving process validation.

Research Studies Using DigiTacts Sensors

Our DigiTacts contact pressure sensors have been successfully used in multiple high-impact research studies, validating their reliability, sensitivity, and versatility in academic and commercial settings:

Soft material 3D force sensing using embedded optical fibres and tactile sensors (ScienceDirect, 2024)

Researchers used DigiTacts tactile pressure sensors to achieve highly accurate 3D force measurements in soft robotic structures, demonstrating improved real-time force reconstruction and enhanced manipulation capabilities.Design of bio-inspired tactile surfaces for robotic fingers (Journal of Robotics and Mechatronics, 2024)

This study integrated DigiTacts contact pressure distribution mapping into bio-inspired robotic finger designs, enabling robots to achieve human-like touch sensitivity and adaptive surface interaction.

These examples highlight the power of DigiTacts technology in delivering precise, real-time contact pressure and tactile pressure data, even in dynamic environments.

Frequently Asked Questions about DigiTacts Sensors

Developed in 2010, PulseTact by PPS brought a new era of simplicity to pulse waveform capture — no complex setups, no precise positioning needed. Today, its DigiTacts technology remains a trusted, embeddable solution for developers seeking high-fidelity, non-invasive pulse data at scale.

Q: What makes DigiTacts different from traditional pressure sensors?

A: DigiTacts use capacitive sensing, offering higher repeatability, faster dynamic response, and improved sensitivity over resistive or piezoelectric alternatives.

Q: Can DigiTacts be customised for my application?

A: Yes! We offer tailored designs in terms of sensor array size, shape, and pressure range to suit your specific project needs.

Q: What communication protocols do DigiTacts support?

A: DigiTacts sensors are available with I²C and SPI digital output interfaces, enabling easy integration into your system.

Q: Do you provide software for data acquisition?

A: Yes, DigiTacts kits come with Chameleon Tactile Visualization and Acquisition Software for easy data visualisation, recording, and analysis.

Why Choose PPS for Contact Pressure Sensing?

For over 30 years, PPS has led the tactile sensing industry, delivering world-class pressure mapping solutions trusted by leading companies, universities, and research institutions worldwide. Our DigiTacts contact pressure sensors offer a powerful, scalable solution for anyone needing compact, accurate, and real-time pressure data.