Ten Years of Engineering Lessons from the TactileGlove

Engineering insights from a decade of development.

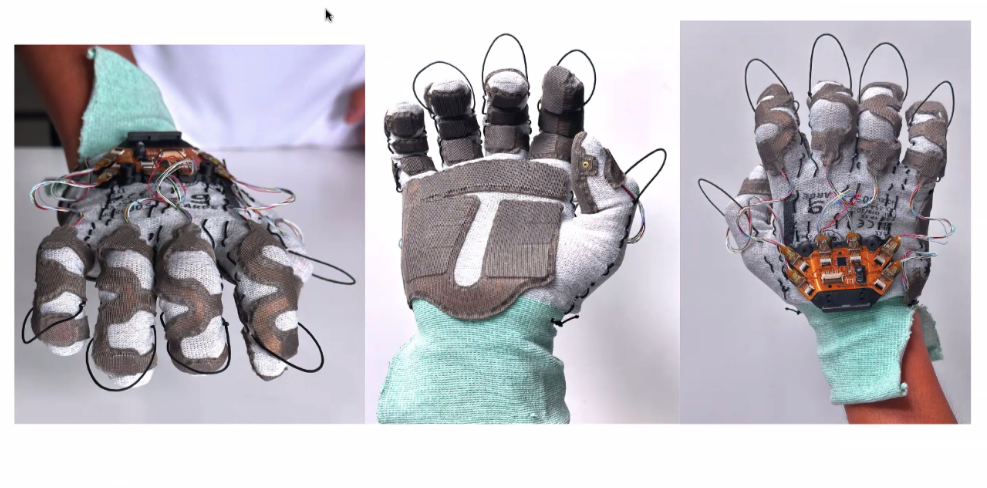

Measuring human touch has always been a difficult engineering challenge. This year, PPS is celebrating 10 years of development of the TactileGlove, a capacitive sensing system that turns hand forces into visual and measurable data. Over the years, the glove has evolved from a fragile prototype into a robust device deployed in industry, healthcare, and sports. However, the journey has been anything but straightforward.

Across multiple generations of the glove, PPS engineers refined wiring, strengthened materials, and adapted designs for real-world use. Here are five of the most significant engineering lessons learned along the way.

1. Internal design defines flexibility.

The earliest prototypes used straight copper Kapton traces to connect 53 sensing elements across the hand and fingers. Under real-world loading, these traces were cracking, especially at high-strain points such as the thumb. Switching to serpentine routing allowed the conductors to flex more naturally, eliminating fracture points.

Wiring presented a similar challenge. Broken conductors, oxidisation, and wires caught in stitching revealed how easily strain could accumulate inside the glove. Redesigns introduced rerouted conductors to avoid stitch lines, along with strain-relief potting at solder pads to reduce stress concentrations.

These refinements improved flexibility and durability, helping the glove withstand regular use without early failure.

Lesson: Reliability begins in the design phase. Eliminating cracks, stress points, and weak connections early ensures the glove can handle everyday use.

2. Glove removal was an afterthought.

When people think about wearable devices, they usually picture putting them on and using them, not taking them off. Yet for the TactileGlove, removal turned out to be one of the most damaging actions. Frequent pinching and pulling at the fingertips put stress on the glove’s interior, causing sensors and wiring to tear apart.

To tackle this, PPS introduced high-strength wire loops designed to absorb stress during removal. Later generations added pull tabs to make the process easier and reduce the risk of damage. But even these fixes had their own challenges: some users found the tabs awkward and didn’t use them, reintroducing the very problems they were meant to solve.

PPS is confident the latest upcoming glove generation resolves this long-standing issue. The company also learned that design improvements must be paired with clear training. Proper usage and removal are now demonstrated at every system delivery handover.

Lesson: Durability alone is not enough. Reliable performance comes from pairing design with clear training on glove removal.

3. Robustness requires reinforcement.

With every iteration of the TactileGlove, robustness has climbed higher on the agenda. Early generations revealed how fragile certain areas could be, from solder pads cracking, traces fatiguing, and even stress points around the palm and thumb giving way after repeated use.

The response was systematic. PPS added reinforced solder pad regions, introduced mechanical stiffeners to absorb stress, and refined pull-tab placement to reduce strain during removal. Each adjustment targeted specific failure points identified through Destructive Part Analysis (DPA).

This incremental approach has paid off. What once failed after only limited cycles of gripping, stretching, or removal now withstands much heavier use. And the work is still ongoing: the upcoming TactileGlove II (Rev 8) incorporates further reinforcements designed to take durability to a new level, addressing lessons gathered over almost a decade of deployment.

Lesson: Achieving robustness requires persistence, identifying weak points and strengthening them one step at a time.

4. The outer glove is more than just a covering.

The evolution of the TactileGlove has shown that the outer layer is as important as the sensing electronics inside. While the inner glove follows standard sizes with hardware mounted externally, the outer cover glove is fully custom-sized, designed specifically to protect the sensors and deliver a good practical fit.

Early smooth-finish versions were let down by bulky seams that made extended wear uncomfortable and raised durability concerns, as seams were prone to fraying. The switch to a custom woven fabric using cut resistant yarn brought major improvements in fit, comfort, and resistance to wear and tear, making the glove lighter and more practical for long-term use. The trade-off was a less polished, more industrial appearance.

Construction refinements soon became as much about protecting the sensors as about user comfort. Later generations added visible higher friction pads ironed onto the outer surface to mark sensor placement, giving researchers and engineers a clearer view of where forces were being measured and improving usability in training and demonstrations.

Lesson: The outer glove is an active part of the system. Its materials, seams, and construction choices directly determine the comfort, durability, and protection of the sensors.

5. Connectivity must match the environment.

The first generation of the TactileGlove (Rev 1, launched 2015) already recognised that solid cable connection could limit usability. It therefore used Bluetooth Low Energy (BLE4) modules to wirelessly transmit data. This provided a scan rate above 40 Hz, a modest range of around 5 m, and enough performance for short-duration research trials. But with just two hours of battery life and limited resilience to interference, it was best suited to laboratory settings rather than busy industrial floors.

As adoption grew, customer feedback was clear: users in manufacturing, ergonomics, and sports needed a greater range, longer sessions, and less chance of signal dropout. To meet this demand, PPS upgraded the system to Bluetooth 5 (BT5). This shift improved usability, supporting 10–50 Hz sampling, faster data transfer, and more reliable communication in environments crowded with competing wireless devices.

The impact was significant. Where the original glove was largely a research tool, today's gloves enable real-time grip analysis, motion capture, and industrial ergonomics studies. Connectivity has become a key factor in transforming the TactileGlove into a system that can be deployed outside the lab and into real-world applications.

Lesson: Connectivity is crucial. Without reliable, interference-resistant data transfer, even the most advanced sensor system is impractical.

Looking ahead

From 2015 to today, the TactileGlove has progressed through at least seven revisions, each driven by lessons from the field. From Kapton traces to Bluetooth 5, and from fragile seams to reinforced pull tabs, every step reflects PPS’s philosophy of learn fast, fix fast, and improve continuously.

The result is a device that doesn’t just measure hand forces; it embodies a decade of engineering insight. The next chapters will focus on further robustness, expanded fit ranges, and perhaps seamless integration into smart factories, rehabilitation systems, and sports performance tools.