Strengths and Limitations of Capacitive Tactile Array Sensors

Capacitive tactile sensors are making a big impact in industries ranging from medical diagnostics to virtual reality. They bring a lot of benefits, but like any technology, they also have some drawbacks. Below, we explore both the advantages and disadvantages of capacitive tactile sensors to provide a clearer understanding of their characteristics and constraints.

Advantages of Capacitive Tactile Sensors

High Sensitivity and Precision

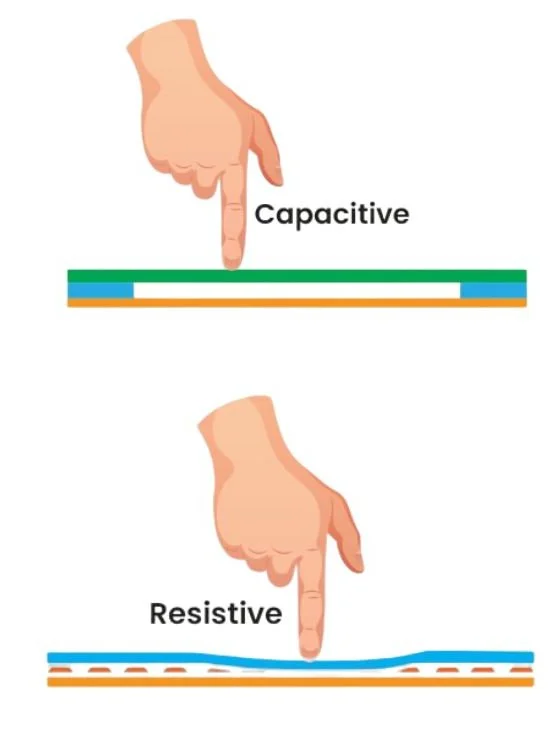

Capacitive tactile sensors are extremely sensitive, picking up even the smallest pressure changes with accuracy. Unlike resistive sensors where electrodes need direct mechanical contact, capacitive sensors detect variations in the electric field. This makes them highly responsive and consistent over time.

Another big plus is their ability to map pressure distribution in detail. This is especially useful in applications where precise force measurement is crucial. Their reliability over repeated use makes them a strong choice for tasks that require consistent and accurate readings.

Durability and Low Maintenance

Because capacitive sensor electrodes don’t rub against one another, they tend to last longer than resistive sensors. With fewer components that can wear out, they remain reliable even with repeated use.

To further enhance durability, many capacitive sensors come with protective coatings that guard against dust, moisture, and general wear and tear. This means they require less maintenance over time, reducing overall costs and ensuring stable long-term performance.

Versatile Design and Material Adaptability

One of the biggest advantages of capacitive sensors is their flexibility in design. They can be made using various conductive materials such as flexible printed circuit boards (FPCB), conductive textiles, and stretchable components. This makes it easier to integrate them into different systems.

Additionally, these sensors can be ultra-thin or even stretchable, which is perfect for applications where space is limited or where they need to conform to curved surfaces. This adaptability makes them a strong candidate for cutting-edge applications in wearable technology and robotics.

Disadvantages of Capacitive Tactile Sensors

Not Ideal for Long-Term Measurement

Capacitive sensors are great for detecting touch and pressure, but they’re not the best choice for measuring weight over long periods, such as hours. When weight is applied, the material between the electrodes can slowly shift (a phenomenon called “creep”), which causes small changes in sensor output - even if the weight stays the same.

For most applications, this isn’t a big issue. But for tasks that require ultra-stable, long-term weight measurement (like industrial scales), alternative solutions like load cells might be a better fit. Some improvements can be made using materials like metal flexors to enhance stability, but it’s important to consider these factors when designing for long term measurement applications.

Scanning Speed Can Be a Limitation

Capacitive sensors with thousands of elements scanning over a large area can take longer compared to some other technologies. This is because the electrodes in the sensor array are arranged in a grid, and each intersection point (capacitor) needs to be scanned individually.

Even with advanced electronics, capacitive sensors may not be the best option for ultra-fast data collection, such as airbag deployment testing or high-speed impact sensing. While scanning speeds can be improved by adding more electronics, this also raises costs, so it’s important to balance speed with budget constraints.

Can Be Affected by Environmental Conditions

Capacitive sensors are highly sensitive, but that also means they can be influenced by environmental factors. For example, when using the sensor applied to the human body, temperature of the sensor going from room temperature to body temperature needs to be considered when precision is paramount.

While atmospheric non condensing moisture effects are minimal, any water ingressing the sensor can change the sensor’s dielectric properties, leading to changes in readings. While protective coatings and sheaths and shielding can help, they add to the overall complexity and cost.

Higher Cost Compared to Resistive Sensors

Although prices have dropped in recent years, resistive sensors still dominate the market due to their lower cost and ease of replacement. Custom capacitive sensors require careful engineering, often involving intricate wiring and flexible cable assemblies, which add to manufacturing costs.

Conclusion

Capacitive tactile sensors combine sensitivity, durability, and versatility, making them a leading choice for industries focused on measuring comfort and fit, robotics, ergonomics, medical devices, and industrial automation. Their ability to detect minute changes reliably ensures stability and durability, allowing them to deliver consistent performance over time.

While challenges such as environmental sensitivity and cost exist, continuous advancements in protective materials, signal processing, and calibration methods have significantly enhanced their reliability. Many of these limitations can be mitigated through thoughtful design adjustments, ensuring that capacitive sensors maintain their high-performance standards in diverse conditions.

As this technology evolves, capacitive tactile sensors are becoming even more adaptable, efficient, and scalable. By leveraging their strengths and addressing their constraints, they continue to offer innovative and high-precision solutions in capacitive tactile sensing.