Heeluxe SmartLast Success Story: Footwear Meets Tactile Sensing

Challenge: Making Shoe Comfort Measurable

When footwear testing specialist Heeluxe set out to change the way shoe fit is measured, they were driven by a single goal. Founder Dr Geoffrey wanted to make comfort measurable in a way that genuinely reflects how people feel in their shoes.

“We’ve always believed that comfort shouldn’t be guesswork,” Geoffrey explains. “If someone can feel tightness, slipping or pressure, then we should be able to measure it. The challenge is building the right tools and making them work at scale.”

Based in Santa Barbara, California, Heeluxe works with major footwear brands to analyse comfort, performance and fit. In 2014, the company developed a pressure-sensor methodology that captured the human experience of tight and loose fit across different shoe categories. This led to category-specific standards for running shoes, dress shoes, casual footwear and hiking boots, and quickly became one of Heeluxe’s most requested services.

However, the success also highlighted a critical limitation: the approach still depended on human testers.

“It worked really well but it simply couldn’t scale,” Geoffrey says. “You can only test so many shoes with real people, no matter how good your process is.”

Heeluxe needed a way to scale human-level perception into a reliable, repeatable, objective measurement system, without losing the nuance of real human experience.

Approach: A Technical Partnership Built for Real-World Needs

Heeluxe began exploring tactile sensing technology and connected with PPS, whose sensors were already being used by a footwear brand they worked with. What started as a search for high-precision sensors grew into a long-term development partnership beginning in 2018.

Geoffrey immediately recognised the quality of PPS’s hardware.

“We’ve built our own systems in the past, so we know when hardware is good,” he explains. “PPS’s sensors were more precise, more consistent, and better suited to the kind of measurement we were aiming for.”

PPS partners with industries requiring high-reliability measurement systems, and this alignment became central to the collaboration. Physical proximity also played a key role — with Heeluxe in Santa Barbara and PPS in Los Angeles, the teams were able to prototype, iterate and troubleshoot in person.

“When you’re creating something that’s never existed before, being able to get in the same room, troubleshoot and refine together makes a huge difference,” Gray adds.

From the outset, PPS’s approach prioritised practicality and performance.

“PPS never tried to dazzle us with tech for tech’s sake,” Geoffrey says. “They kept us focused on what mattered: performance, consistency and results for brands and their customers. Anytime we drifted toward ‘nice-to-have’ features, they pulled us back.”

Solution: SmartLast — The World’s First Precision System for Measuring Shoe Fit

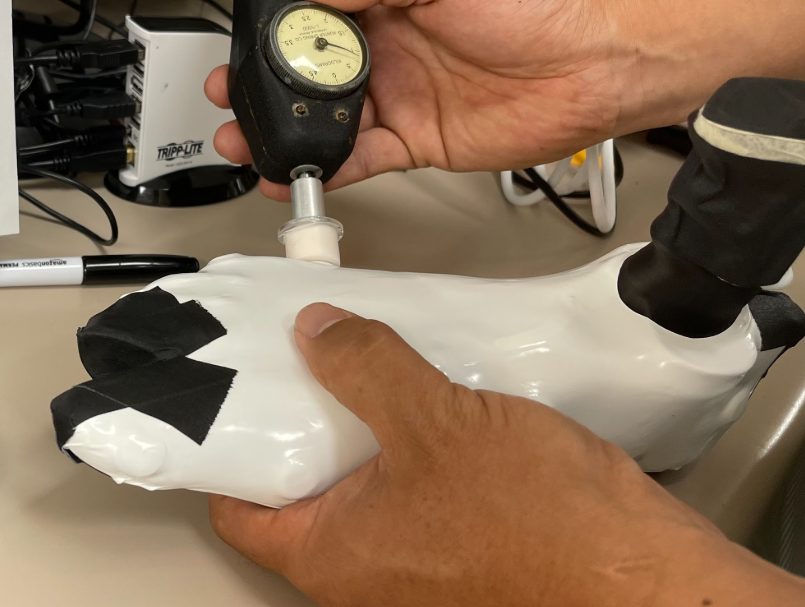

Together, PPS and Heeluxe developed SmartLast — the first precision measurement system capable of replicating and quantifying true human shoe-fit perception.

By combining PPS’s tactile sensing technology with Heeluxe’s footwear expertise, the two teams built a system capable of delivering laboratory-level accuracy at production speed. SmartLast reduces test time from days or weeks to just 30 seconds, revolutionising how footwear is evaluated and refined.

According to Zappos catalogue analysis, a typical timeline for a full human-based testing approach would take 34 years. SmartLast was launched in 2020 after only two years of strategic planning and development.

The footwear industry’s previous experiences with unreliable fit-measurement tools meant SmartLast needed to be exceptionally trustworthy.

“The footwear industry is incredibly small and interconnected,” Gray explains. “There’ve been tools in the past that promised to measure fit and comfort but didn’t hold up in the real world. When that happens, people remember.”

“If even one system failed in the field, we’d lose trust immediately,” says Geoffrey . “Reliability wasn’t a target, it was survival.”

PPS’s technical precision and reliability were critical in making SmartLast fit for global deployment.

“By focusing on practicality, performance, and scalability, PPS helped turn SmartLast from an ambitious idea into a globally deployable system trusted by more than 60 leading footwear brands,” Gray added.

Results: Scalable, Repeatable Fit Measurement for the Global Footwear Industry

Since launch, SmartLast has transformed fit testing for footwear companies around the world.

Today, more than 60 footwear brands use SmartLast annually for fit analysis, with systems deployed across California, Japan, Vietnam, the Czech Republic and the United Arab Emirates.

The project also led to Heeluxe’s FitGalaxie database - a scientific catalogue of over 9,000 measured shoes. Brands and retailers now use this data to benchmark fit, analyse competitors and make data-driven design decisions.

Before SmartLast, Heeluxe’s human testers regularly found variation of ½ to a full shoe size between models, even within the same brand. SmartLast’s sensor-based measurements reduced typical variation down to ⅛ of a size, creating more reliable fit consistency and improving consumer confidence.

As Gray explains: “SmartLast allows brands to guarantee that a customer’s size will feel the same every time they buy, regardless of the shoe type.”

Future Outlook: A Roadmap of Continued Innovation

What began as a single sensor-supply project has evolved into a long-term innovation partnership.

“We’re both companies full of curious people,” Gray says. “PPS brings ideas, challenges us, and helps push things further. That ultimately makes our products better.”

A joint roadmap is already underway, including:

• hardware upgrades for factory-level fit tracking

• integration of customer-feedback and online review data

• exploration of a Kids SmartLast system for youth footwear testing

These developments reflect a partnership built on trust, one where PPS’s reliability and technical precision continue to support Heeluxe’s mission to make the world’s shoes fit better.

“PPS became a valuable innovation partner,” concluded Gray. “Their reliability made it possible for us to help improve the footwear industry.”