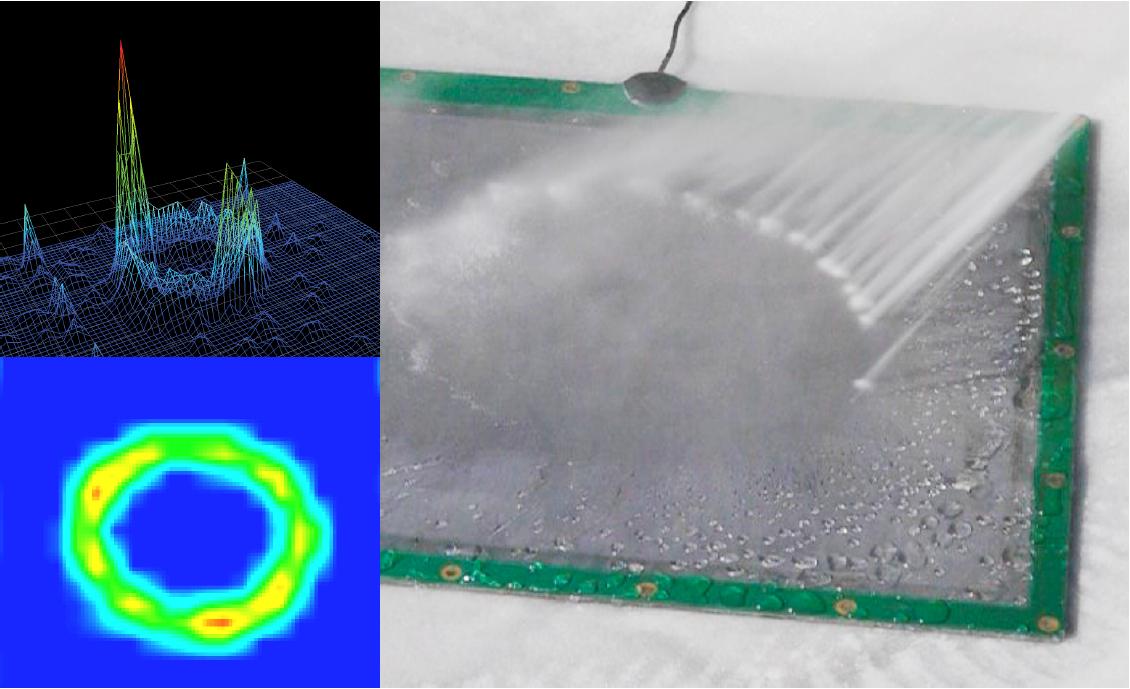

Spray Pattern Sensor

The Spray Pattern Measurement System is a first-of-its-kind large, high-speed sensor mat designed to visualize and characterize accumulated fluid deposition information for spray processes and is able to identify where a sprayed fluid or gas actually land.

The Spray Pattern Measurement System was designed for manufacturing, process engineers and researchers who are working with spray and/or coating processes involving very fine mists and who need to understand specific spray patterns as part of a manufacturing or coating process to control the quality of the finished product.

Many spray process requirements are met only through “trial and error”, meaning numerous adjustments to achieve a desired result. PPS’s Spray Pattern Measurement System addresses this problem by digitizing, visualizing, and quantifying fluid deposition patterns that enable real-time feedback and electronic records for comparison and analysis, providing new levels of insight into spray and coating processes.

Features:

High resolution array sensor images the amount of fluid deposited over an area and provides instantaneous feedback for quick adjustments or analysis.

Ability to measure fluid deposition even for applications in which pressure is infinitesimal.

Waterproofed Sensor Mat capable of providing valuable data under any spray process conditions. This data shortens development time and helps improve the quality and cost of products and processes.

High performance capacitive sensing technology saves time and improves results by significantly reducing recalibration and repeated tests allowing developers to resolve problems and answer questions faster.

High speed USB 2.0 interface provides latency-free results.

Chameleon Visualization Software provides intuitive, easy to use, high-quality visualization and easy access to data for analysis and export to other applications.